Lithium battery cells have become an indispensable part of modern life, powering our smartphones, laptops, electric vehicles, and even large-scale energy storage systems. However, with the vast array of lithium battery products available, selecting a high-quality lithium battery cell can be a daunting task. This article will delve into the world of lithium battery cells, providing you with comprehensive knowledge and a step-by-step guide to help you make an informed decision.

1. Demystifying Lithium Battery Cells

At the heart of every lithium battery lies the lithium battery cell, composed of a positive electrode, a negative electrode, an electrolyte, and a separator. The chemical reaction between the positive and negative electrode materials generates electrical energy, while the electrolyte facilitates ion transport, and the separator prevents direct contact between the electrodes, ensuring safe operation.

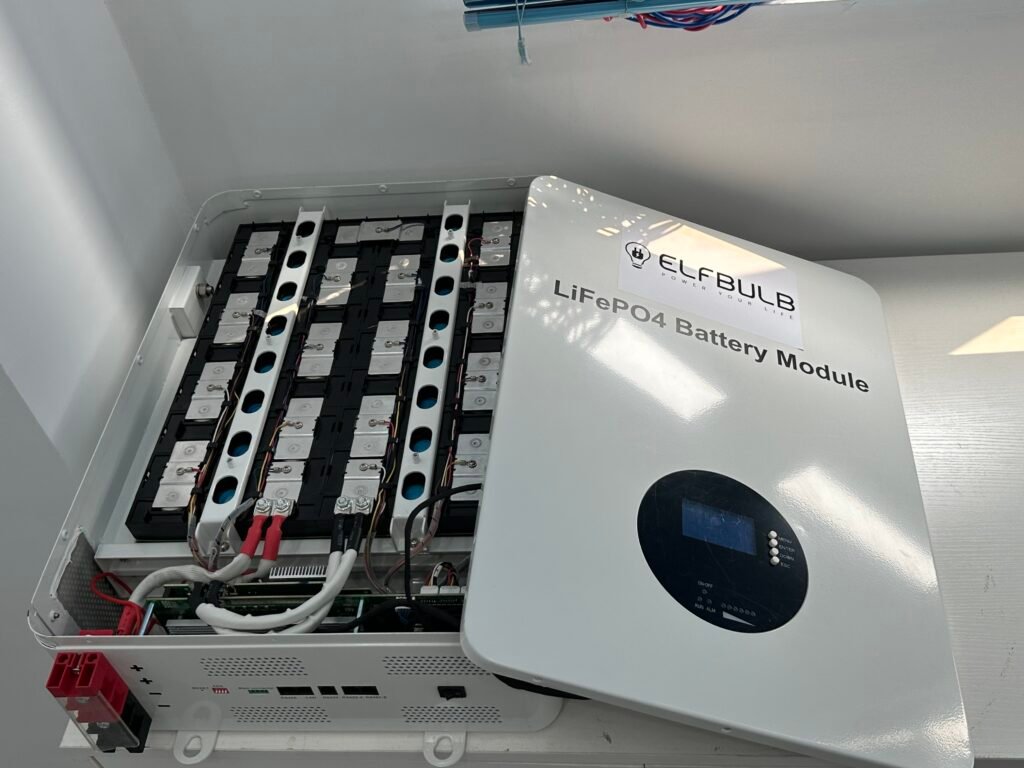

Lithium battery cells can be categorized into three main types based on their shape: cylindrical, prismatic, and pouch cells, each with its own set of advantages and drawbacks.

- Cylindrical batteries: Compact, high energy density, low cost, but relatively lower safety.

- Prismatic batteries: Enhanced safety, efficient heat dissipation, customizable, but slightly lower energy density.

- Pouch batteries: Flexible, lightweight, highly customizable, but larger in size.

2. Renowned Lithium Battery Cell Brands

The global lithium battery cell industry is populated by numerous outstanding manufacturers, some of which have established themselves as industry leaders and gained the trust of consumers:

- CATL (Contemporary Amperex Technology Limited): A Chinese powerhouse, the world’s largest producer of power batteries, leading the way in technology and production capacity.

- BYD (Build Your Dreams): A prominent Chinese(New Energy Vehicle) manufacturer, boasting a complete lithium battery supply chain and excelling in cost control.

- Gotion High-Tech: A distinguished Chinese lithium battery company specializing in power battery manufacturing, holding a competitive edge in prismatic batteries.

- EVE Energy: A prominent Chinese lithium battery enterprise primarily focused on the production of lithium iron phosphate batteries, offering exceptional cost-performance.

- CALB (China Aviation Lithium Battery): A Chinese military enterprise at the forefront of lithium battery technology for aerospace applications.

- Envision Power: A well-known new energy company in China, focusing on the R&D and manufacturing of energy storage batteries, it has launched energy storage battery core products with high safety, long life and high energy density.

- Hithium: A well-known lithium battery company in China, focusing on the R&D and manufacturing of energy storage batteries, it has launched cost-effective large-capacity energy storage battery products.

3. Selecting the Ideal Lithium Battery Cell: A Comprehensive Guide

When making your choice of a lithium battery cell, carefully consider the following factors based on your specific needs:

- Application Scenario: Different applications demand varying battery performance characteristics. For instance, electric vehicles require high energy density batteries, while energy storage systems prioritize long lifespans and high safety standards.

- Performance Metrics: Pay close attention to crucial battery specifications such as energy density, cycle life, charging speed, and operating temperature range.

- Brand and Price: Opting for reputable brands ensures quality and售后服务(after-sales service). Simultaneously, balance your budget with product performance to select the most cost-effective option.

4. Frequently Asked Questions (FAQs) about Lithium Battery Cells

1. Can lithium battery cells explode?

Answer: Theoretically, any battery can explode; however, lithium battery cells are relatively safer. By choosing qualified products from reputable brands and adhering to proper usage and maintenance guidelines, the risk of explosion is minimized.

2. Are lithium battery cells allowed on airplanes?

Answer: Yes, but subject to airline regulations. Generally, passengers can carry no more than two lithium battery cells, each with a rated energy of no more than 270Wh.

3. How to maintain lithium battery cells?

Answer: Shield lithium battery cells from extreme heat and humidity, and maintain their performance through regular charging and discharging cycles.

Conclusion

Lithium battery cells play a pivotal role in technological advancements, significantly enhancing our lives. We hope this comprehensive guide has empowered you with the knowledge and tools to make informed decisions and select the most suitable lithium battery cell for your needs.